Performance Chiptuning EPB Chipbox Vauxhall Opel Astra G H J MK4 / MK5 Petrol

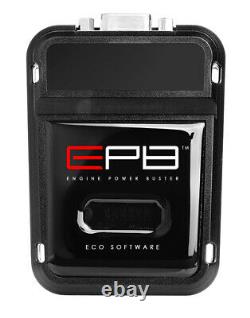

Engine Power Buster Chipbox software digital tuning. Brand new 2021 edition with new generation tuning software. We are currently operating as normal and orders are being processed and dispatched on a daily basis. Can't find your car in our store? ECU tuning software: latest edition. Cable set with original plug. User manual in 5 languages + photos. Type of the processor: Engine Flash _Based. CPU Speed: Flash 36 Million operations. Engine protection software: latest edition. DIY 30 seconds Plug and Drive installation. EPB Chipbox is connected directly via diagnostic port which is required to be within 2 feet (0.6 meter) of the steering wheel. All cars manufactured after 1999 are equipetwith it.

Original, high-quality and fully digital product made in Europe. 24/7/365 dedicated customer service team. Support the health system in your country. Engine Power Buster Chipbox: the only direct ECU software tuning device available on the market.

Fundamentally, the engine ECU controls the injection of the fuel and, in petrol engines, the timing of the spark to ignite it. It determines the position of the engines internals using a Crankshaft Position Sensor so that the injectors and ignition system are activated at precisely the correct time.An internal combustion engine is essentially a big air pump that powers itself using fuel. As the air is sucked in, enough fuel has to be provided to create power to sustain the engines operation while having a useful amount left over to propel the car when required.

This combination of air and fuel is called a mixture. Too much mixture and the engine will be full throttle, too little and the engine will not be able to power itself or the car. Not only is the amount of mixture important, but the ratio of that mixture has to be correct. Too much fuel - too little oxygen, and the combustion is dirty and wasteful.

The temperature of the air also plays a role in combustion quality in much the same way as the varying atmospheric pressure. Since a car engine spends most of its time at part throttle, the ECU concentrates on maximum efficiency in this area. The ideal mixture, where all of the injected fuel is combusted and all oxygen is consumed by this combustion, is known as stoichiometric or often as Lambda. At stoichiometric conditions, Lambda = 1.0. The Exhaust Gas Oxygen Sensor (Lambda sensor, O2 Sensor, Oxygen Sensor or HEGO) measures the amount of oxygen left over after combustion.

This tells the engine whether there is an excess of air in the mixture ratio and naturally whether there is excessive or insufficient fuel being injected. The ECU will read this measurement, and constantly adjust the fuel quantity injected to keep the mixture as close to Lambda = 1.0 as possible. This is known as closed loop operation, and is a major contribution to the advanced efficiency that comes from using engine ECUs. Because of the strict emissions regulations now in force, there are many other systems on an engine that help to reduce fuel consumption and/or environmental impact. Catalytic converter and Selective Catalytic Reduction. Exhaust Air Injection Reaction (AIR). Exhaust Additive Injection (Such as AdBlue). Variable Valvetrain Control (Such as VTEC or MultiAir). Each of the above systems affect engine operation in some way and as a consequence need to be under full control of the ECU. How does an ECU work? An ECU is often referred to as the brain of the engine. It is essentially a computer, a switching system and power management system in a very small case. To perform even on a basic level, it has to incorporate 4 different areas of operation. Requests from the Antilock Brake System (ABS) module may also be considered, such as for the application of traction control. Once the data has been collected by the ECU, the processor must determine output specifications, such as fuel injector pulse width, as directed by the software stored within the unit. The processor not only reads the software to decide the appropriate output, it also records its own information, such as learned mixture adjustments and mileage. Output The ECU can then perform an action on the engine, allowing the correct amount of power to control actuators precisely. These can include controlling fuel injector pulse width, exact timing of the ignition system, opening of an electronic throttle body or the activation of a radiator cooling fan.The first stage of ECU operation is in fact power management. This is where various voltages are regulated and the power-up of the ECU is handled. Most ECUs have sophisticated power management due to the variety of components inside, accurately regulating 1.8V, 2.6V, 3.3V, 5V, 30V and upto 250V all from the cars 10-15V supply. The power management system also allows the ECU to have full control over when it powers itself down i. Not necessarily when you turn off the ignition switch.

Once the correct voltages are supplied, the microprocessors can begin to boot up. Here the main microprocessor reads software from the memory and performs a self-check. It then reads data from the numerous sensors on the engine and converts them into useful information.This information is often transmitted over the CANbus your cars internal computer network to other electronic modules. Once the main microprocessor has interpreted this information, it refers to the numeric tables or formulae within the software and activates outputs as required. Should the Crankshaft Position Sensor show the engine is about to reach maximum compression on one of the cylinders, it will activate a transistor for the relevant ignition coil.

The aforementioned formula and tables within the software will cause the activation of this transistor to be delayed or advanced based on throttle position, coolant temperature, air temperature, EGR opening, mixture ratio and previous measurements showing incorrect combustion. The operation of the main processor inside the ECU and the activation of many outputs is overseen by a monitoring microprocessor essentially a second computer that makes sure the main computer is doing everything correctly. If the monitoring microprocessor is not happy with any aspect of the ECU, it has the power to reset the whole system or shut it down completely. The use of the monitoring processor became imperative with the application of drive-by-wire throttle control due to safety concerns should the main microprocessor develop a fault.

With efficiency of engine operation and efficiency in car assembly moving forward, electronic throttle control was introduced. This sped up the manufacture of a car (no stiff throttle cables passing through the firewall), it removed the need for an Idle Air Control valve and it allowed the engine ECU additional control over the engine for improved EGR function, improved control over engine shutdown and improved starting.One important advantage of electronic throttle control is that the ECU can adjust the throttle angle during acceleration to compliment the actual airflow through the engine. This improves the speed at which the air passes through the intake and provides gains in torque and drivability. This is known as torque-mapping and is only possible with electronic throttle control.

Up to 33% more horse power: higher max. Up to 33% more torque. More force to either accelerate your car or pull a load with. Individual fine-tuning maps: tuning dedicated to individual ECU software. Smooth ride and turbo-hole removal. The EPB Chipbox comes with 12 pre loaded tuning maps to ensure you get the most efficient results. Being completely plug and play, our tuning boxes have the added advantage thet they cannot be wiped when your car goes in for a service. What is Engine Power Buster Chipbox? Nowadays, car manufacturers construct just a certain number of engine types and assign the power output with the use of Electronic Control Unit (same hardware, different software). Our team of experts specialise in car tuning software.Their crowning achievement is software that reads the data from the ECU and modifies it to fit individual vehicles. Engine Power Buster Chipbox modify the performance of your vehicle only within the manufacturers limits, ensuring long-endurance of the engine and leaving existing engine protection intact. What is ECU and how it works? An electronic control unit (ECU) controls a series of actuators on an internal combustion engine. To ensure optimal engine performance.

It does this by reading values from a multitude of sensors within the engine bay, interpreting the data using multidimensional performance maps called lookup. , and adjusting the engine actuators accordingly. How does Engine Power Buster Chipbox works and what parameters are modified?Using our new generation ecu software tuning device is not the same thing as doing the permanent tuning (remap) via diagnostic connector at a garage. Remaps are a permanent install and cannot be removed before servicing. They are not adjustable and cannot be turned off. Our unique device can be removed any time you wish within 10 seconds, leaving no traces behind.

ECU with an attached Engine Power Buster Chipbox controls the amount of fuel to be injected. This varies depending on the engine's RPM and the position of the accelerator pedal (or the manifold air pressure). The tuning can adjust this by bringing up a spreadsheet-like page where each cell represents an intersection between a specific RPM value and an accelerator pedal position (or the throttle position, as it is called).

In this cell a number corresponding to the amount of fuel to be injected is entered. This spreadsheet is often referred to as a fuel table or fuel. Our products increase the torque which allows to change gears earlier. The vehicle accelerates better with sooner upshift, driving with overall lower RPM value, letting you save up to 12% of fuel. Has Engine Power Buster Chipbox got negative influence on my car's condition?The use of our original products does not cause any damages to the engine or its components. The EPB Chipbox unit is an additional control device. This means, it modifies and optimises the values of the manufacturers engine control unit and thus increases the performance of the vehicle. Engine protection functions are not bypassed or deactivated, therefore adverse values are detected and blocked by the engine control unit.

So, you dont have to worry about the engine, gear and other vehicle components. With no limits thanks to unique, exclusive and patented software. Monitors functioning of the engine and its components. It guarantees the safety of the engine and its longevity. SEPS is provided only with our original devices! Our products leave no traces. Car dealers or mechanics are not able to detect our product when its unplugged. All you have to do, is unplug it before your service appointment and attach it back after it. Carrying out the installation procedure will not be needed as the chipbox has already saved all the settings. Do your products have quality certificates and are they original? Our production process meets the highest standards of International Association of Manufacturers and Electronics Industry (IPC) as well as European and International standards of high quality production. IPC certifications are recognised as a Guarantee of Quality of products and services in the electronics industry. Application of IEC standards during manufacture ensures high quality and repeatability of the process. All aspects of our products including: hardware, software, logo, brand name and case are registered and patented.CUSTOM DUTY FREE SHOPPING FOR ALL CUSTOMER OUTSIDE OF EU ZONE. WE ALWAYS USE THE ADDRESS ON YOUR PAY PAL ACCOUNT AT THE TIME OF ORDER. Please be aware that we cannot accept liability for any expenses incurred because of delayed or unsuccessful deliveries.

An order placed before the cut off time for the day (12.30PM) would be dispatched the same day. Your satisfaction is our greatest priority and you can be sure we will try to solve any issues that you might have. You will receive all the informations after your order. The item "Performance Chiptuning EPB Chipbox Vauxhall Opel Astra G H J MK4 / MK5 Petrol" is in sale since Saturday, June 20, 2015. This item is in the category "Vehicle Parts & Accessories\Car Tuning & Styling\Engine, Tuning & Chips\Performance Chips". The seller is "enginepowerbuster" and is located in DUBLIN. This item can be shipped worldwide.- Warranty Period: 5 YEARS

- Type: Chip Tuning

- Part Manufacturer Number: 56Y56Y4

- Manufacturer Part Number: EPB979594F

- Placement on Vehicle: Front

- Other Part Number: Y45Y45Y4

- Brand: PRO S